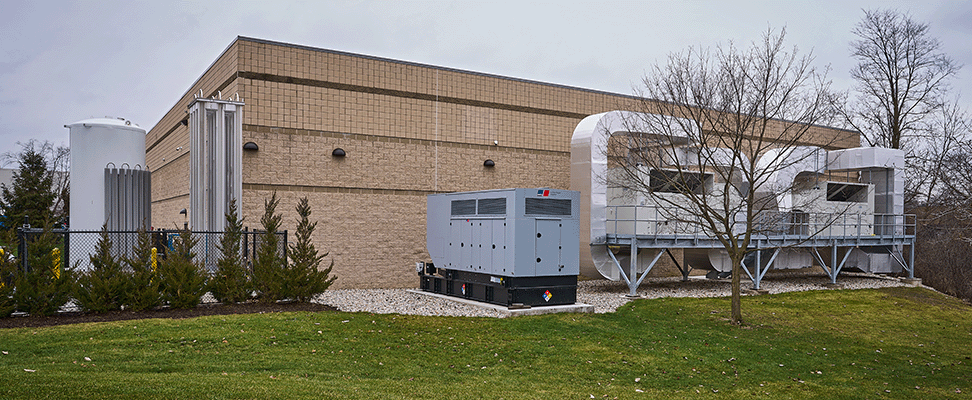

Oliver / Hatcher Construction was the Design-Builder of a new state-of-the-art 3D Titanium Printing Laboratory for Materialise in Plymouth, Michigan. The new Laboratory, designed by HED, includes a modern clean room, quality control workrooms, as well as ample space for 3D printing technology used to create medical devices for various industries.

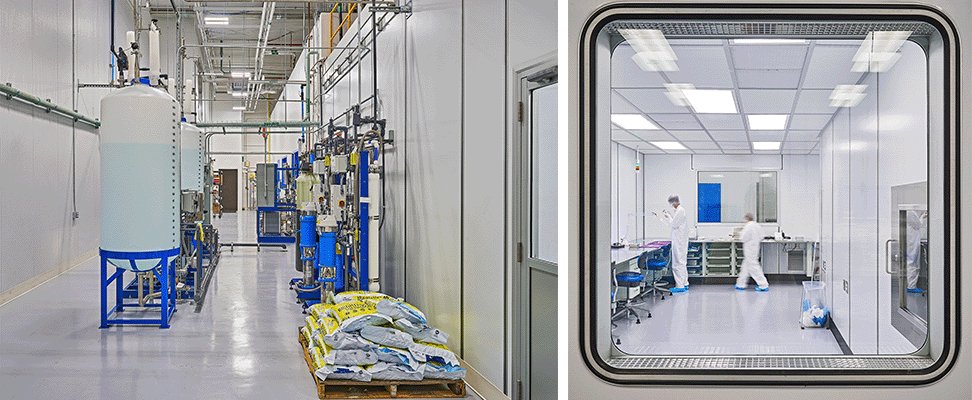

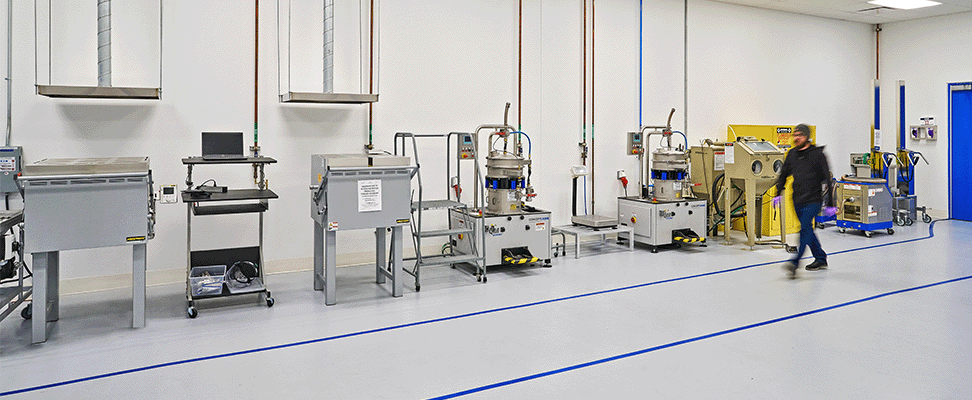

The design and construction of Titanium Printing Laboratories are specialized to provide a controlled environment for the 3D printing devices including cleaning and packaging. The ISO 7 Clean Room provides air cleanliness levels of a maximum of 10,000 particles (≥0.5µm) per cubic foot and a minimum of 60 air changes per hour. Before entering the clean room for final packaging, a device will originate in the printing laboratory, then pass through the post-processing area, quality control room, and pre-cleaning stations.

The new clean room includes locked side-by-side fire-rated wall panels, anodized aluminum frame doors, chemically resisted floors, and a high-efficiency air filtration HVAC system.

Previously, OHC completed a design-build renovation of the Materialise facility while the building was occupied. Special attention and careful procedures were followed while working in close vicinity of vibration to sensitive equipment.

“Starting up our Medical Metal 3D printing facility in Materialise USA was not an easy task, especially not with my remote role from Belgium. We knew from the early start that selecting the right general contractor was key in delivering this project successfully on time. From the moment OHC stepped in with the weekly meetings, I really felt comfortable in the way the project was managed. It’s a pleasure for a customer that you really listened to our requests and did everything possible to meet our timeline which was the most critical parameter for this project. Despite several severe setbacks we were able together to do the right things and install back-up solutions to not jeopardize the overall Materialise timeline. In the end, after all our Materialise validations, we only had two weeks delay on this big project, which is really perceived as a big achievement. The core values on your website, love what you do, do what’s right every time, and relationship driven, shine through everything you do, and it indicates that it’s not just a marketing phrase.

Special thanks to the whole OHC team and subcontractors for keeping up with the challenging timeline. I think the whole team performed very well and Materialise is a happy customer once again.”

– Ken Boumans, Technical Production Manager, Materialise